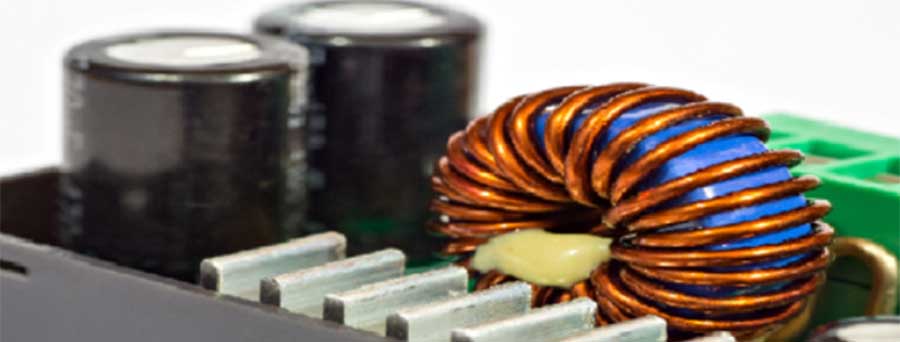

A toroidal coil is a type of coil that is wound in the shape of a torus, which is a donut-like shape. For custom coil winding, the following steps can be followed:

Determine the specifications: The first step in winding a custom toroidal coil is to determine the desired specifications, such as the number of turns, the wire gauge, and the target inductance.

Determine the specifications: The first step in winding a custom toroidal coil is to determine the desired specifications, such as the number of turns, the wire gauge, and the target inductance.- Prepare the toroidal core: A toroidal core is needed to form the shape of the toroidal coil. The core should be cleaned and secured in a jig to keep it stable while winding.

- Start winding: The wire is wound around the toroidal core in a circular pattern. The winding direction and the number of turns can be determined based on the desired specifications.

- Secure the wire: Once the desired number of turns have been wound, the end of the wire should be secured to prevent it from unraveling. This can be done by wrapping the end around the last turn of the wire or using a small amount of adhesive.

- Check the inductance: The inductance of the coil can be measured using a multimeter or an inductance meter to verify that it meets the desired specifications.

- Insulation: If desired, the toroidal coil can be coated with insulation to protect the wire and improve its performance.

Custom toroidal coils can be wound with various wire materials and in different sizes to meet the specific requirements of different applications. This type of coil is commonly used in electronics and electrical engineering because of its high inductance and low profile.