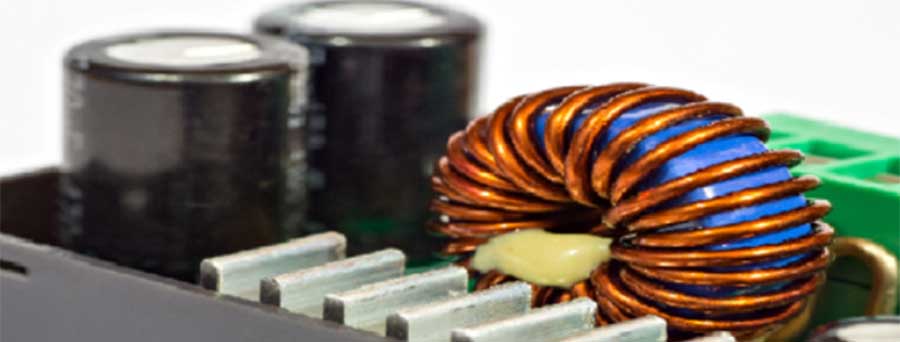

Coil winding is essential in producing electrical components, such as inductors, transformers, and electromagnets. The core of this process involves winding conductive wire, also known as the winding, into a series of loops called turns. Custom coil winding enables the creation of specialized wire coils tailored to specific applications and requirements.

Wire Insulation and Coating

In windings where the turns are in contact, insulating the wire with a nonconductive coating, such as plastic or enamel, is crucial. This insulation prevents electrical current from passing between the turns, ensuring the proper functioning and safety of the component. Depending on the application’s needs, bare and coated wires can be used in custom coil winding processes.

In windings where the turns are in contact, insulating the wire with a nonconductive coating, such as plastic or enamel, is crucial. This insulation prevents electrical current from passing between the turns, ensuring the proper functioning and safety of the component. Depending on the application’s needs, bare and coated wires can be used in custom coil winding processes.

Specialty Wire Coils and Bending

Custom wire coil winding and bending often involve working with a wide range of wire gauges, from bare copper AWG 2-42 to coated copper AWG 2-42. Depending on the design specifications and intended application, thinner wires are generally wound on Toroid or plastic bobbins. Thicker wires, on the other hand, can create air or stand-alone coils. Each type of wire offers unique properties that cater to different electrical and mechanical requirements.

Current Frequency Options in Custom Coil Winding

Wire coils are classified based on the frequency of the current. The following are the primary current frequency options for custom coil winding:

- Direct current (DC) coils or electromagnets: These components operate with a steady direct current in their windings, making them suitable for applications requiring constant magnetic fields or continuous current flow.

- Audio-frequency (AF) coils, inductors, or transformers: These components are commonly used in audio equipment and signal processing applications as they can operate with alternating currents in AF range (below 20 kHz).

- Radio-frequency (RF) coils, inductors, or transformers: These components function with alternating currents in the radio frequency range (above 20 kHz) and are typically found in communication devices, wireless transmission systems, and other high-frequency applications.