Toroidal transformers are ring-like in shape, and they are used to help power electronics. It is made from a magnetic core that includes ferrite, powdered iron, or laminated iron. Because of the shape and materials used, a toroid suffers from minimal electromagnetic interference. Engineers use toroids because they increase the overall efficiency of the equipment they work within.

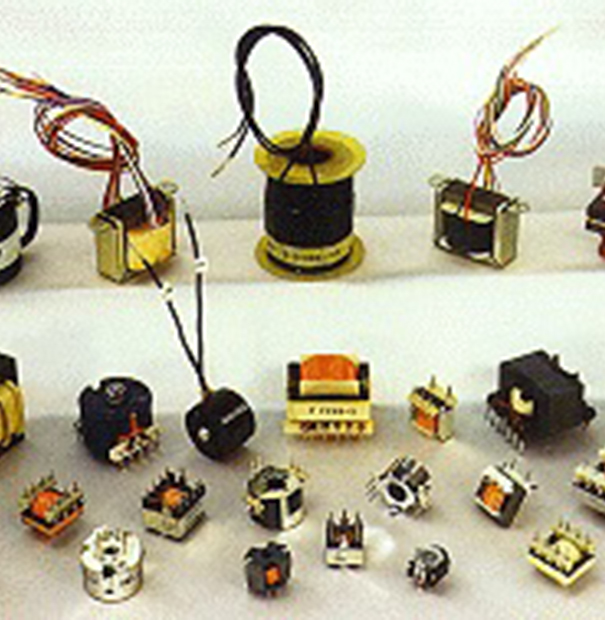

Custom coil winding is done in highly compact configurations to allow toroids to function differently depending on the desired application.

The primary purpose of a transformer is to enable changes in voltage levels as required. On the other hand, a custom toroidal power transformer has clear advantages of other similar sized and powered transformers. The main reason a toroid is often the best choice is because of its size and shape. Inputs are connected to primary custom coil windings. While currents pass through the winding, the current develops a positive magnetic field. Voltage begins to drop, and then the positive magnetic field becomes negative. Negative and positive magnetic fields then pass through secondary winding, which generates an output voltage. The total amount of voltage created is directly proportional to the turn ratio between the primary and secondary winding.

Custom Coil Winding

The core helps maintain magnetic fields as they build and collapse. This induces a maximum voltage in secondary windings. Overall, it improves the efficiency of the transformer.

Related Reading

- Frequently Asked Questions for Designing Toroids

To design toroidal transformers that meet exact application requirements, you need to ask important questions about what toroids are, how they work, and how to create them.

- Learning About Toroids and Custom Coil Winding

- Integrating Toroidal Transformers into Your Design